Deliver the Best Print Output with the Right Labels

Posted by Admin on 17th Nov 2020

A clear and nicely labeled product can be a surefire winning strategy for creating and selling a product. With a proper label applied to your products, you can enhance the visual appeal of the products to a great extent. However, you need to know what type of labels you need to select for which product whether thermal transfer or direct thermal labels.

The main purpose of using labels is not limited to draw the attention of customers only, it is equally important to establish the brand. A brilliantly printed label with product information and company logo can make a huge impact and can put you easily ahead of the race. You can find important information about direct and indirect type thermal labels in the following paragraphs.

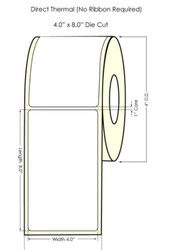

Direct Thermal Type Labels

Direct thermal labels remain very cost-effective labels for use with direct thermal printers. The direct thermal printing process involves a thermal print head that heats the coated thermal papers in specific places. The paper turns black when gets heated and produces the desired image, as it passes over the thermal printing head.

The common application of such types of labels is for poultry, meat, and dairy products, where the direct thermal type labels are being used for a long time. However, with the improvement in technology in direct thermal printing and labels, there are many more uses of these labels, and a few key uses are as follows:

- For Barcodes used in various products, specifically for visitors, and patient identification, shipping labels, ticket, and receipt printing.

- Visitor passes and name tags.

- Coupons, and event tickets, and many more.

Further, the direct thermal printing labels come with several advantages like the ability to print continuous sheets or reels in an effortless way. Such labels are very cost-effective to create large quantities of simple labels. The operating cost of the direct thermal printers is low as compared to other types of printers and such printers are also environmentally sustainable.

A few other key benefits are that the direct thermal printing labels are that it saves time for reloading and monitoring of the printing process. Moreover, direct thermal printing labels do not wrinkle and can reduce the need for physical inventory.

Thermal Transfer Type Labels

Thermal transfer printing labels are used in thermal transfer printers, where standard labels along with carbon ribbon are used. The ribbon located between the label and printhead, when heated, transfers the ink to the label. The use of thermal transfer labels enables producing highly durable and crisp prints, and for such reason, it is highly suitable for use in high-density bar-code printing.

Further, the use of direct thermal printing labels may not be suitable for many applications that require to remain in the original condition for a long time. Also, such labels are not suitable for harsh environment, where the use of thermal transfer type labels produce a much better result. The typical use of thermal transfer printing labels is logistics, warehouse and tracing, and tracking application, and for several demanding applications and harsh environment.